Cost effective light weighting for commercial transportation using thermoplastic honeycomb technology: from PP and recycled PET through to high performance thermoplastics

EconCore group, world leader in economic honeycomb sandwich material production technology, is announcing at IAA Transportation its innovations that are set to massively contribute to circular economy.

The group, consisting of EconCore NV in Belgium and the German ThermHex Waben GmbH focusing on production of PP honeycomb core and PP honeycomb panels, just installed a new production line for lightweight honeycombs based on recycled PET (RPET).

The new line is capable of production of RPET honeycomb core in widths up to 1.2m. At the same time, the unique design of the line allows for processing of other thermoplastic materials such as polycarbonate, polyamide or polyetherimide (high-performance-thermoplastics, HPT).

The developments of RPET honeycomb technology have been triggered by an increasing demand and market shift towards the use of more recyclable materials. The EconCore team is well advanced in developments across a wide range of industries, including automotive, transport, construction and, with regard to HPT honeycomb, also aerospace. These sectors are developing a growing appetite for lightweight materials produced sustainably.

EconCore’s lightweight honeycomb material solutions are an excellent fit for the transportation industry. Light weighting has emerged as key element in fleet owner strategy to increase fuel efficiency, lower emissions, optimize payload, and out on the road a fleet of vehicles that is safer, more reliable and having improved life cycles.

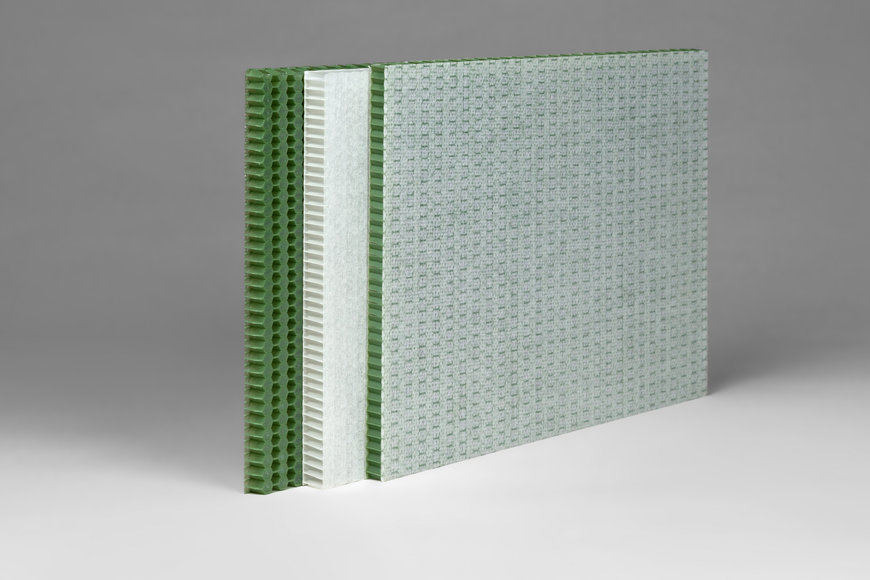

The PP honeycomb core of ThermHex Waben is already a very popular solution within a range of truck body and trailer applications such as side walls, roofing, flooring, doors, shelves, partitions and interior cladding. In most of these cases the PP honeycomb is laminated into a sandwich panel with FRP composite skins. Other customers prefer to use semi-finished ThermHex honeycomb panels with PP/GF thermoplastic skin layers in order to benefit from even higher weight saving potential, improved toughness of thermoplastic composites, and, of course, from a fully recyclable sandwich panel solution.

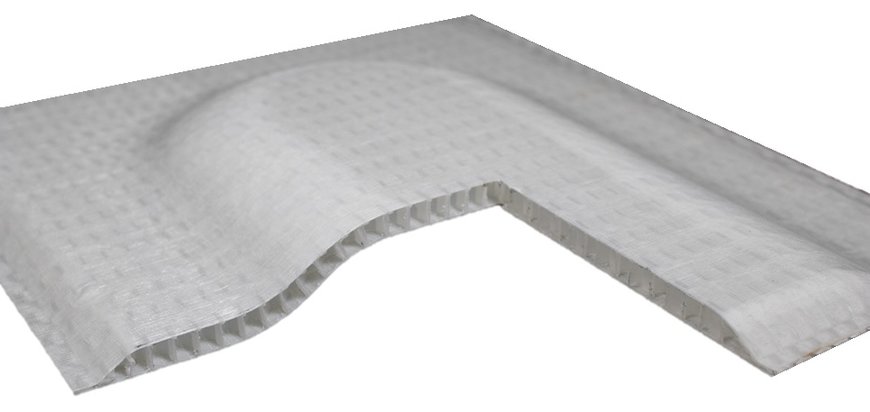

RPET honeycomb cores are made of up to 100% recycled post-consumer and post-industrial waste. These honeycomb cores can be laminated with conventional FRPs into performing sandwich panels and parts. In combination with PET or PET composite skins, they offer fully recyclable, highly sustainable and lightweight panel solution.

“The demand for development of sustainable material solutions is very evident these days and it runs through the DNA of EconCore,” “Over the past years we have been extending the range of applications of our PP honeycomb technology where its cost and weight efficiency, combined with excellent recyclability were allowing for dynamic market evolutions. Then, recognizing the global problem of agglomerated PET waste, we decided to optimise the technology towards RPET materials.” “This development was immediately recognised - we just won the European Green Award and were awarded the prestigious Solar Impulse Label. But most rewarding is the interest we receive from the industry. We are already engaged in development programs over a wide spectrum of applications where the cost, weight and sustainability are of critical importance,” Tomasz Czarnecki, Chief Operations Officer at EconCore, said.

With the PP and RPET honeycomb technology, not only are the various industries able to improve their own impact on the environment by stripping out weight in transport, for example, but also EconCore’s energy efficient production process itself brings benefits with regard to carbon footprint positioning. It is a win all round.

At IAA Transportation, EconCore group will be featuring the RPET honeycomb technology along with ThermHex Waben’s lightweight honeycomb cores and their new offering of lightweight PP honeycomb panels. The PP sandwich panels, an in-line produced laminate of PP honeycomb core and PP/glass fibre skins, are an excellent (up to 80% weight saving) replacement of plywood, monolithic panels and other conventional materials.

They exhibit an outstanding performance-to-cost ratio, easy recyclability, and – for applications requiring parts of complex geometries – they can be compression moulded in an effective one-step process. The PP honeycomb panel is ideal for large series production of components for the automotive and transportation industry, where the performance, light-weighting and cost-efficiency need to meet together.

EconCore will also present its high-performance-thermoplastic honeycomb technology addressing the needs of demanding applications, including railway and aerospace.

If you would like to learn more about the group’s thermoplastic honeycomb solutions, you can meet the sales team on Stand A30, Hall H25, or alternatively visit the website:

- https://econcore.com/en/products-applications/RPET-honeycomb-core.

- https://thermhex.com/products/organosandwich/

- https://thermhex.com/products/pp-honeycomb-cores/