www.auto-innovations.net

31

'23

Written on Modified on

Hexagon Manufacturing Intelligence News

HEXAGON MITIGATES NOISE AND VIBRATION WITH OPTIMAL DAMPING TREATMENT DESIGN

With many decades of experience in NVH CAE simulations, and strong partnerships aimed at optimising and standardising processes in NVH design, Hexagon is charting the course into the future of the mobility.

Electrification and rising fuel prices lead automakers to focus on reducing component mass while maintaining excellent noise and vibration performance. Conducting high-accuracy Noise, Vibration and Harshness (NVH) analyses during the early design phase is crucial to achieving this goal. Moreover, it is equally important to consider production constraints while upholding the essence of the design.

One of the big challenges for automakers is structure-borne noise at low frequencies. To reduce this noise, employing high-performance acoustic treatments is essential but must not add unnecessary weight or cost. Autoneum, one of the leading manufacturers of acoustic and thermal insulation materials for vehicles, has a long history of successfully using its internal workflow for solving this challenge.

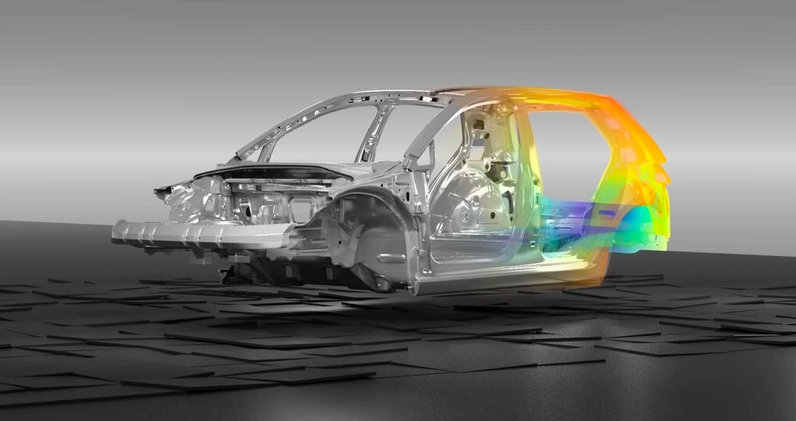

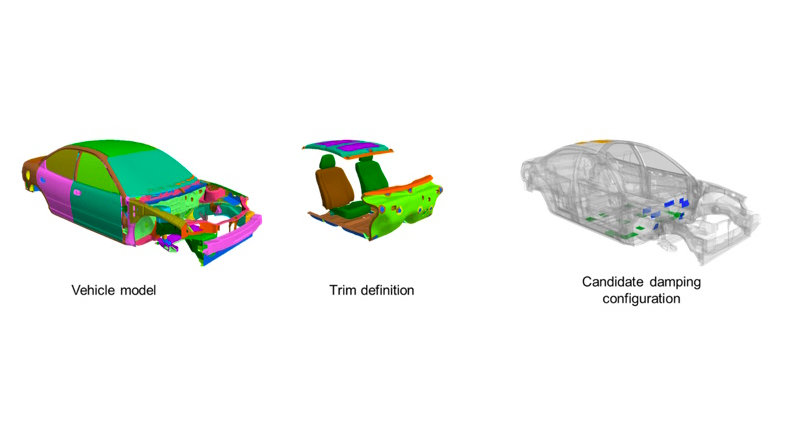

Figure 1: Models for evaluating vehicle NVH performance

To democratise this workflow, Autoneum and Hexagon have worked together to integrate Autoneum’s state-of-the-art simulation process within the Actran Workflow Manager, a unified interface for creating vertical applications. Thanks to the Actran Workflow Manager, engineers can adjust the location, size, shape, and thickness of the treatments and easily assess their effectiveness by comparing multiple configurations and rapidly performing what-if analyses through a guided process, and removing the burden of complex pre- and post-processing tasks. MSC Nastran models can be post-processed, edited and relaunched from the Actran Workflow Manager user interface, providing more actionable information and a fluid user experience when iterating on multiple configurations.

Figure 2: Damping pad positioning workflow within the Actran Workflow Manager

Users are weighing up the merits of more sustainable materials by evaluating several conflicting constraints such as NVH, cost and weight. By implementing best practices from Autoneum and Hexagon into a single environment, Hexagon offers a robust and systematic workflow making it easier to get actionable insights. Overall, this is an important step to fulfilling Hexagon’s mission to provide manufacturers with the tools and capabilities to obtain the highest cost saving and an optimal NVH design.