www.auto-innovations.net

04

'23

Written on Modified on

Renault Group News

FUTURE CMF-B EV PLATFORM ELECTRIC RENAULT 5 PROTOTYPES BEGIN ENDURANCE TESTING AND FINE-TUNING

A first, decisive step in designing the future production model: testing the very first electric car prototypes, also known as ‘mules’, on all types of terrain and grip, including in extremely cold conditions.

To further develop and fine-tune the future electric Renault 5, Renault experts are currently testing its first nine prototypes. Known as mules, their platform, power train and battery are technically the same as the future production vehicle. With a design based on the Clio silhouette, the mules do not yet look like the future model. A keen pair of eyes will also notice that these mules have a recharge hatch.

Alternating between static and dynamic fine-tuning and endurance testing, the mules are being put through their paces this winter in low grip (ice, snow) conditions in Arvidsjaur (Swedish Lapland) as well as average-to-high grip conditions at the Renault technical centres in Lardy (greater Paris area) and Aubevoye (Normandy).

The Aubevoye technical centre: Reproducing anything end clients will put their car through

The Renault site in Aubevoye is unique in that it has the means and cutting-edge tools to reproduce any types of stress vehicles will be put through at the hands of customers: 613 hectares, 35 tracks covering 60km, 42 test lines, 2 wind tunnels, 18 corrosion chambers, all hidden within 272 hectares of forest to shield the prototypes from prying eyes.

Freezing-cold extreme condition testing

Testing carried out not far from the Arctic Circle in the Arvidsjaur region in the far north of Sweden is ideal for putting the vehicle under extreme stress. A land of ice and frozen lakes, where some winter days nudge -30°C with almost unbearable howling winds. The vehicle's mechanical performance is put to the test to make sure that the future electric Renault 5 mules can withstand such temperatures and conditions. The engine along with other parts – including the batteries – are placed under close surveillance. Checks are also carried out on the performance of on-board systems such as heating, demisting, and defrosting, and to make sure that the brakes, shock absorbers, and ESC (Electronic Stability Control) perform as they should on snow. Tests are also carried out to make sure that powder snow does not pile up on the brakes, as it may lead to vehicle malfunctions. A vast array of parameters that cannot be replicated in a testing facility, where only real-world cold-weather testing will suffice.

The CMF-B EV platform out for its first spin

Used for the first time on the future electric Renault 5, the new CMF-B EV platform will have to take on its position as the most competitive in its segment, while offering best-in-class performance. The platform has therefore taken 70% of the parts featured on the CMF-B platform used for Clio and Captur. Compared to ZOE, the CMF-B EV platform is 30% cheaper to manufacture.

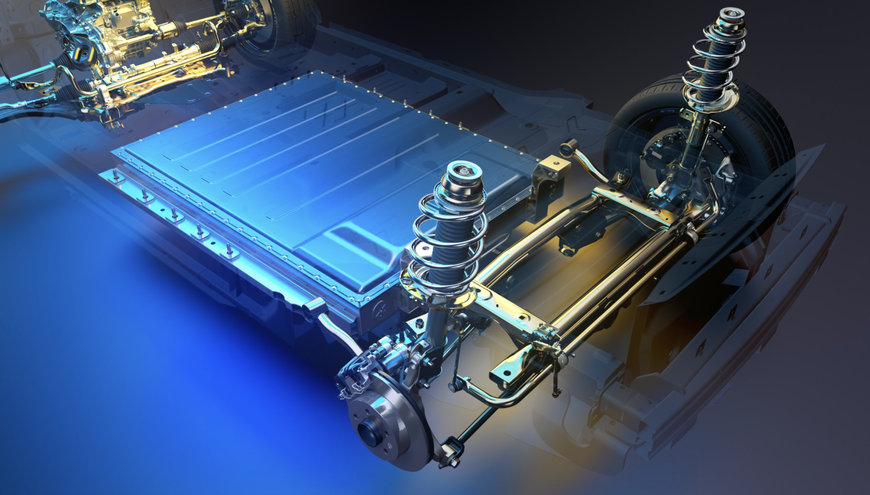

The new modular platform is easier to make, develop, and optimize the performance of next-generation B-segment electric vehicles. The advantages of the new design mean that a new generation of electric vehicles can be created, with adjustable tracks and wheelbase to allow for different body types and styles. Like the Megane E-Tech electric, the future electric Renault 5 will be the benchmark for its segment in terms of driving pleasure. The optimized chassis with a multi-link rear axle (usually reserved for more prestige segments) and a lower centre of gravity with batteries installed under the floor will ensure greater dynamic performance.

The new engine and batteries also put through their paces

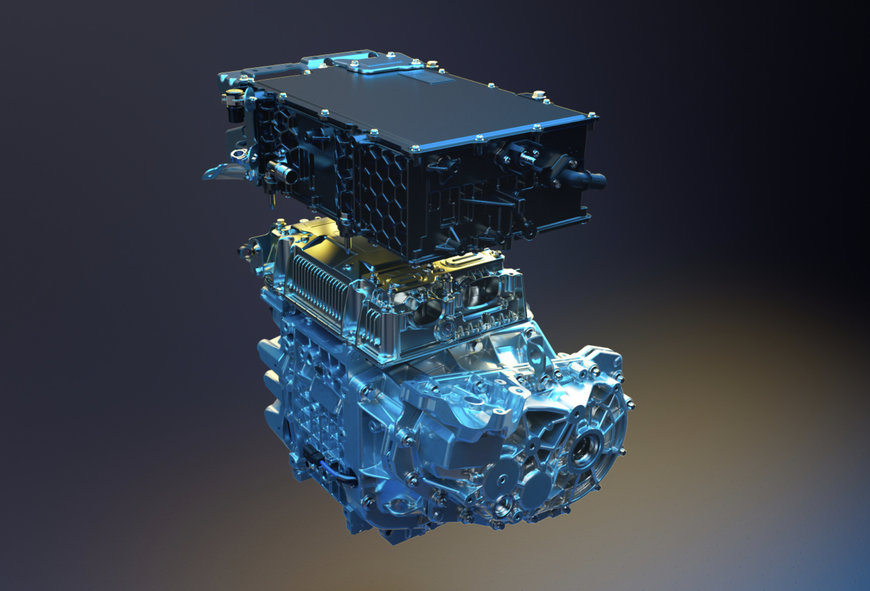

The CMF-B EV platform engine compartment is more compact because the parts used for an electric motor are smaller than those used on an internal combustion engine.

The electric motor on the future electric Renault 5 will be based on the tried-and-tested electrically excited synchronous motor used primarily on the ZOE and Megane E-Tech electric. Not only does it boast better output than a permanent-magnet motor, but it also requires no rare-earth metals meaning that large-scale production costs and the environmental impact are both lower.

Moreover, the engine will benefit from a new internal architecture, combining three main components:

- the DC/DC converter that converts the battery’s 400V into 12V.

- the battery charger

- the accessory box that manages power distribution

By pooling together the different functions performed by these three components in a single box, the engine is smaller and lighter. Roughly 20kg lighter than that used for the ZOE, the future electric Renault 5 engine will be more enjoyable and dynamic to drive than its predecessor.

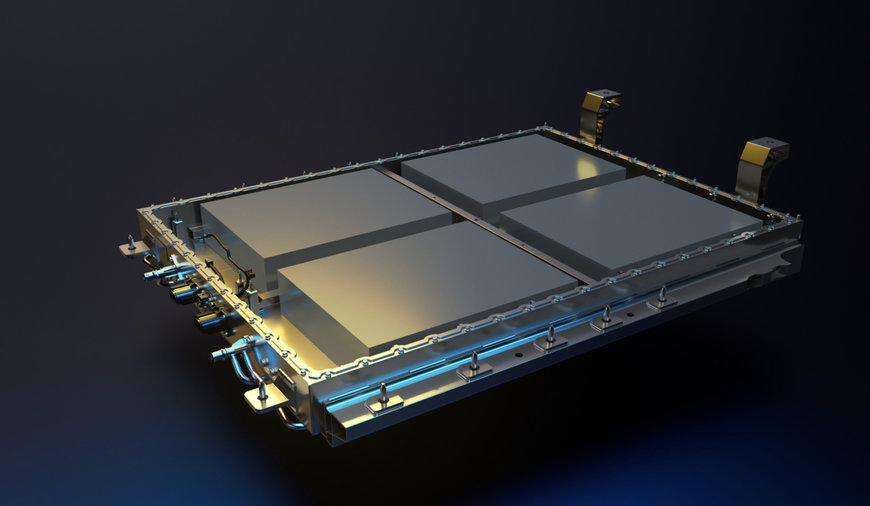

The new battery pack will also help give the vehicle the competitive edge sought after by Renault. The switch from the 12 modules seen on the ZOE battery to 4 large modules means the architecture is simpler and 15kg lighter. Equipped with a single layer of modules, the battery pack is a perfect fit for the new platform. The future electric Renault 5 will need less space to transport more kWh.

Special care has also been taken to house the battery pack inside the platform for added protection. Its placement will provide added rigidity to the under body, thereby also improving the acoustics and driving pleasure.

www.renaultgroup.com