www.auto-innovations.net

22

'23

Written on Modified on

ONSEMI News

Onsemi Straight Up: A Better Approach to Cooling Semiconductors

While it may not be immediately apparent due to the relatively large size of vehicles, the space available for technology solutions in vehicles is generally quite small and cramped.

The primary reason for this is that most of the available space is given to the passenger cabin and electronic systems are tucked away in out-of-the-way spaces.

While this makes sense, it does make cooling these solutions challenging – especially as power levels are high in many automotive applications. Therefore, the industry continues to seek ways in which cooling may be improved, delivering a number of benefits to automakers and vehicle owners.

In this technical article, onsemi will look at how innovations at the semiconductor package level are making huge strides in improving thermal management within modern automotive applications.

As vehicles move to electric propulsion and many systems that were previously mechanical or hydraulic are replaced with electrical actuators, the amount of high-power conversion on modern vehicles is rising significantly. Huge efforts and significant budgets are being expended to increase the overall efficiency of these new electrical systems, primarily to increase the range of the vehicle.

However, greater efficiency has another benefit for the system designer, the generation of waste heat is significantly reduced. From a thermal management perspective this means that cooling techniques such as heatsinks can be reduced or removed entirely, thereby reducing the size, weight and cost of the solution.

In fact, as any power engineer will know, the best way to remove heat is to not generate it in the first place. The second best thing is to ensure that any waste energy has as direct a path as possible to ambient air.

While wide-bandgap technologies such as silicon carbide (SiC) have made huge leaps in efficiency improvement, there is not (and probably never will be) a power device that does not incur some energy loss.

Conventional approaches to cooling semiconductors

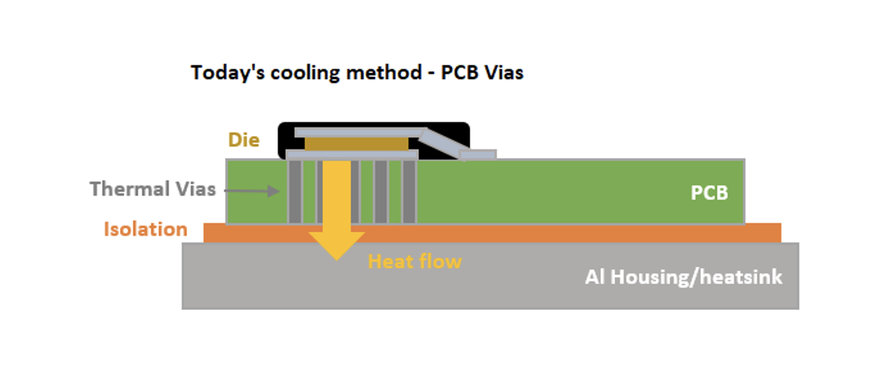

In power applications, metal–oxide–semiconductor field-effect transistors (MOSFETs) tend to be surface mount devices (SMD) such as SO8FL, u8FL, and LFPAK package types. SMD is the preferred technology as it gives good power capability and the convenience of automatic placement and soldering as well as making for a compact solution. However, the heat dissipation with SMD devices is not ideal because the heat propagation path usually travels through the printed circuit board (PCB).

Conventional cooling requires heat to travel via the PCB to a heatsink.

In conventional components, the lead frame, including an exposed drain pad, is soldered directly onto a copper footprint on the PCB which provides an electrical connection and a thermal path from the die to the PCB. This is the only direct galvanic thermal connection to the PCB as the rest of the device is enclosed in a mold compound and cooled only through convection to surrounding air.

With this approach, the efficiency of heat transfer away from the device is heavily dependent on PCB properties such as the copper (Cu) plane size, Cu layers, Cu weight, and Cu layout. This holds true whether the board is attached to a heatsink, or not. As a result of the restricted thermal path, the maximum power capability of the device is restricted as the low thermal conductivity of the PCB impedes heat dissipation.

The Top Cool concept

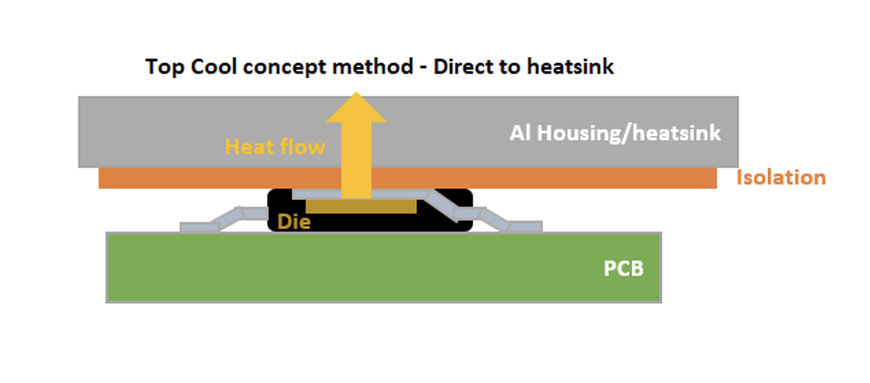

To address this issue, onsemi has developed a new MOSFET package that exposes the lead frame (drain) on the top side of the package. This approach brings benefits in both application layout / space, and in thermal transfer.

While the traditional approach to cooling power MOSFETs is able to deliver reasonably compact solutions, the underside of the PCB must remain unpopulated to allow for a heatsink to be applied. In this approach, a larger PCB is generally required to accommodate all necessary components.

Top Cool devices place the heatsink above, improving layout and thermal performance.

As the thermal path is upwards with Top Cool devices, the heatsink is place above the MOSFETs, allowing placement of components such as power devices, gate drivers and other components on the underside, thereby permitting a smaller PCB to be used. This more compact layout also allows for shorter gate drive traces which can be a benefit in high frequency operation.

Additionally, as there is no longer a requirement for the heat to pass through the PCB, the PCB itself will remain cooler and components surrounding the MOSFETs will operate at lower temperatures which will improve their reliability.

Alongside the layout benefits of Top Cool devices, there are also significant thermal benefits as the package allows for direct heatsinking to the lead frame of the device. The most commonly used heatsinks are aluminum due to the high thermal conductivity (typically between 100 − 210 W/mk). Aluminum, or similar metals, greatly reduce the thermal resistance compared to conventional heatsinking via a PCB, thereby delivering a better thermal response.

In addition to improved thermal conductivity,heatsinks provide a much greater thermal mass which helps avoid saturation, providing a longer thermal time constant as the top mounted heatsink can be sized to suit the application needs.

Given the benefit of being directly attached to a high thermal mass heatsink, the top cool package will have a better thermal response, measured as temperature rise per Watt. This enhanced thermal response allows for higher power operation for a given junction temperature increase.

Ultimately, the same MOSFET die packaged in a Top Cool package will have higher current and power capability than the same die placed in a standard SMD package.

New range of Top Cool N-Channel MOSFETs

onsemi has developed a range of Top Cool devices that are housed in a modified LFPAK 5x7 package measuring just 5mm x 7mm. Designated the TCPAK57, the new Top Cool package features a 16.5mm2 thermal pad on the top side, allowing heat to be dissipated directly into a heatsink.

Internally, the TCPAK57 devices feature a copper clip for the source and drain connections. This replaces the wire bonds and allows conduction of large currents with minimal resistance, as well as an effective thermal connection to the top side pad. The new devices deliver the electrical efficiency required in high power applications with RDS(ON) values as low as 1mΩ.

This solution leverages onsemi’s deep expertise in packaging to provide the highest power density solution in the industry. The TCPAK57 initial portfolio includes a total of seven devices, rated at 40V, 60V and 80V. All devices are capable of operating at junction temperatures (Tj) of 175°C and are AEC-Q101 qualified and PPAP capable. This, along with their gull wings that allows inspection of solder joints and superior board level reliability, makes them ideally suited to demanding automotive applications. The target applications are high/medium power motor controls such as electric power steering and oil pumps.

The Top Cool TCPAK57 devices provide increased power density and the improved reliability of the new design adds to an extended overall system lifetime.

Summary

Managing heat in power designs is fundamental to achieving the challenging design goals that exist in the automotive industry. Conventionally, cooling discrete power devices such as MOSFETs involved passing thermal energy through the PCB to a heatsink. However, this is not an ideal thermal path and, consequently, device performance was hampered.

However, a new package style moves the thermal pad to the top, thereby allowing a heatsink to be bonded directly to the device. Not only does this improve cooling of the MOSFET, it also allows the underside of the PCB to be used for component placement, thereby increasing power density in critical applications such as automotive.

www.onsemi.com