www.auto-innovations.net

06

'23

Written on Modified on

TDK LAUNCHES HIGH-VOLTAGE CONTACTORS FOR ELECTRIC VEHICLES

HVCs are mission critical in electric vehicles, but also in charging stations, commercial use vehicles, uninterrupted power supplies, and energy storage systems for renewable energies.

Today’s high voltage batteries used in electrical vehicles offer maximum safety and longevity. If you have been hesitating about whether to swap your gas-powered car for an electric vehicle (EV) because of concerns about battery safety—rest easy! HV Batteries are extremely safe when used under normal operating conditions with problems being relatively rare. In fact, HV Batteries for EVs are similar to your digital clock’s batteries – uncomplicated, reliable, and safe.

The Importance of HV Batteries in Electric Vehicles

In contrast to the batteries used in internal combustion engines (ICE), which are primarily used to start the engine and power auxiliary features like the air conditioner or music system, the battery in an EV essentially powers each and every component from the engine to the vehicle’s computer to the power windows.

HV Batteries are also a significant part of the vehicle’s overall cost, making up between 30% and 40% of the total price for a new EV. With that price point, you want to be sure your HV Battery operates safely and efficiently for the maximum possible time.

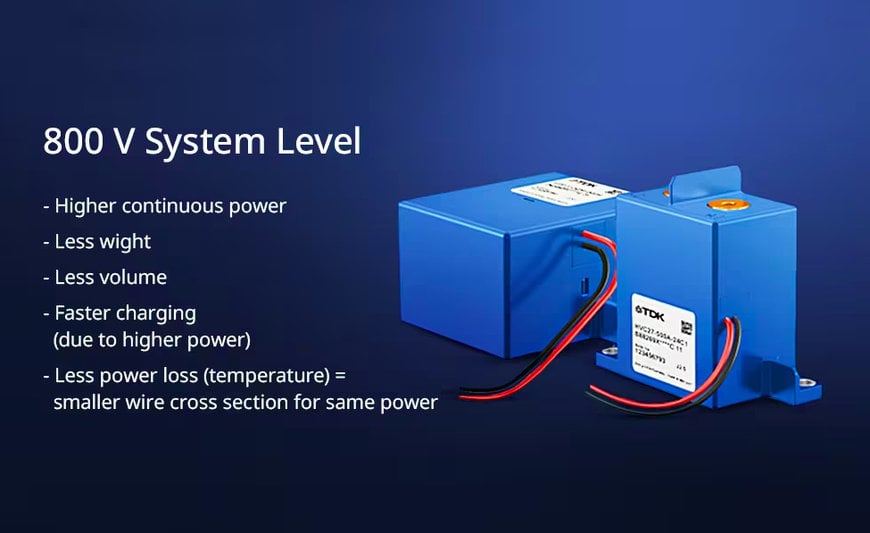

The Coming Era of 800 V HV Batteries

With the launch of 800 V batteries in 2019 (doubling the capacity of the standard 400 V engine battery), automakers began making higher-powered vehicles with a lower weight, faster charging time, and increased safety. In fact, an 800 V engine battery can charge up to 80% in just over 20 minutes, compared to 40 minutes when using a standard 400 V battery.

However, 800 V HV batteries are only being used in a small number of vehicles at this time, although that number should increase as manufacturing technology expands at more of the major automotive companies.

A Major Part of Battery Safety — DC Power Contactors

TDK has launched a series of High-Voltage contactors designed for the demands of high current DC contactor relay applications. HVCs are mission critical in electric vehicles, but also in charging stations, commercial use vehicles, like buses, trucks, and heavy equipment, uninterrupted power supplies, and energy storage systems for renewable energies.

How High Voltage Contactors Improve Safety

TDK’s HVCs are designed with safety in mind. As part of an electric vehicle’s Battery Disconnect Unit (BDU), high voltage DC contactors are part of a system designed to disconnect the battery and extinguish the arc evolving in the contactor in the event of an emergency or malfunction. Such failures can include battery or mechanical issues or damage caused externally.

By extending the range of DC high voltage contactors, TDK’s new HVC43 series has smaller dimensions and is 30% lighter than previous models. Made for smaller currents up to 250 A, the gas-filled ceramic arc chambers are designed to quickly disconnect and extinguish high loads used in today’s EVs.

Summing Up

The technology to further improve HV battery safety continues, with TDK soon launching an industry-first design of the HVC DC contactors with improved short circuit performance.

Today, car owners have a choice that may be more in line with their values without sacrificing safety and convenience. This means that drivers can experience vehicle safety and performance more in line with traditional gas-powered vehicles while also helping to improve the environment—a win-win situation for everyone!

www.tdk.com