www.auto-innovations.net

25

'23

Written on Modified on

Vibracoustic News

All-new electric AC compressor encapsulation improves NVH-performance

Vibracoustic has developed an encapsulation and mounting solution for the electric refrigerant compressors found in electrified vehicles. The Encapsulated eCompressor Bracket provides substantial NVH improvements over conventional mounts.

With the global surge in electrification – particularly battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) – Vibracoustic is proactively leveraging the experience and expertise of its R&D teams to develop new NVH solutions to key OEM challenges. This latest innovation, an Encapsulated eCompressor Bracket, has been designed to solve some of the NVH issues specific to the use of electric AC compressors, which are used in BEVs and other electrified vehicles.

By researching and evaluating new NVH challenges of BEVs, Vibracoustic identified the requirement for a product that could effectively manage eCompressor NVH. Unlike gasoline- or diesel-powered vehicles where such noises and vibrations are masked by the combustion engine, sound and excitations emitted by auxiliary systems like eCompressors are much more noticeable in quiet, refined BEVs. Using a holistic-vehicle approach, Vibracoustic’s engineers were able to identify a broad range of unwanted frequencies, caused by the e-motor and the compression device of eCompressors. Not only did these cause body vibrations but also undesired radiated noises – particularly when the vehicle was stationary or recharging.

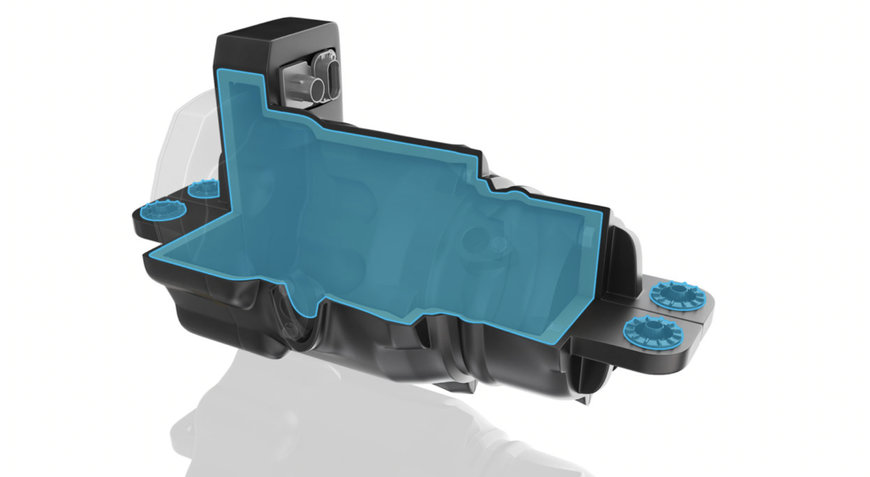

The Encapsulated eCompressor Bracket combines solutions for both structure-borne and air-borne disturbances to deliver comprehensive NVH management. The solution uses a two-piece plastic housing lined with high-frequency sound absorbing material, with the two halves completely enclosing and embedding the eCompressor. This housing is paired with elastomer mounts for low frequency isolation and straightforward vehicle integration. Alongside significantly improved NVH performance, the system’s plastic bracket allows for better load distribution while assembly is simplified with the consolidation of two separate products.

Early prototype applications of the Encapsulated eCompressor Bracket have demonstrated considerable improvements – both measured in an anechoic chamber and audibly obvious – over conventional solutions. Testing has also demonstrated that complete encapsulation does not lead to thermal issues, but instead may offer minor improvements in compressor efficiency.

Dr. Jörg Böcking, CTO at Vibracoustic, commented: “While the rapid transition to electrified and electric vehicles has brought many challenges to the automotive industry, our engineers continue to pioneer ingenious solutions for emerging OEM applications. Our Encapsulated eCompressor Bracket solves the acoustic and vibrational issues associated with eCompressor use, particularly while charging or stationary, further enhancing passenger comfort, perceptions of quality and the ownership experience. It is yet another example of our talented global team providing innovative NVH solutions that further enable the e-mobility transition.”

www.vibracoustic.com