www.auto-innovations.net

18

'22

Written on Modified on

dSPACE News

Battery Management Systems: High-Precision Validation and Optimization with a New dSPACE Solution

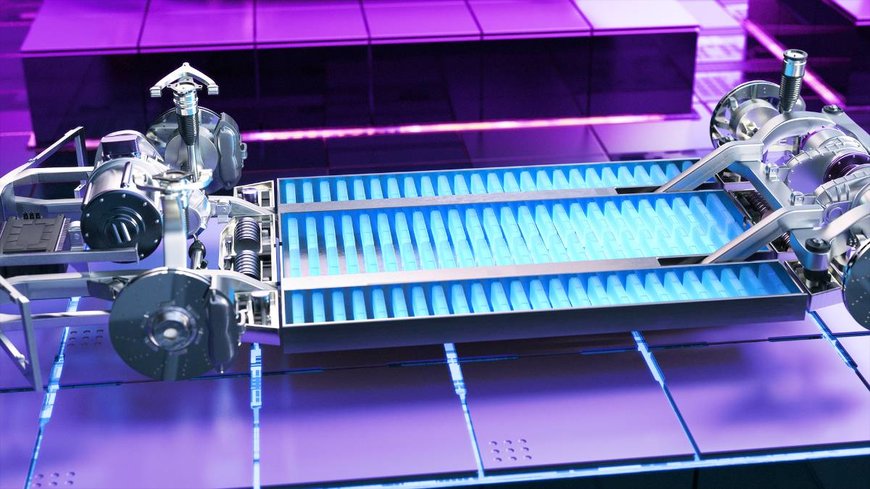

dSPACE is launching a modular system concept for testing battery management systems. The new solution will let users test modern battery systems with overall voltages of up to 1,500 V. Its innovative core component is a high-precision cell voltage emulation board.

The new, powerful BMS solution integrates seamlessly into the tried-and-tested SCALEXIO technology and can be configured to meet the requirements of each individual customer. When combined with the simulation software ASM Electric Components, which provides a comprehensive library of battery models, it can be used right immediately. Its field of application ranges from the development and validation of battery systems for electromobility to energy storage systems for modern power grids.

Battery management systems are crucial for the smooth operation of lithium-ion batteries as they manage the efficient use of available capacity, ensure optimum temperatures, and avoid overcharging as well as deep discharges, thereby ensuring safe operation and long life of the energy storage systems. High-performance energy storage systems are gaining in importance for electromobility and a variety of other industrial applications, where increasingly demanding performance requirements call for battery systems with ever higher voltages.

The modular system design has been designed specifically for these and further requirements. It supports the validation of battery systems up to 1,500 V. The low-latency, real-time-capable integration of the cell voltage emulation to the SCALEXIO system via IOCNET allows for fast updates of the individually emulated cell voltages independent of the number of cells and size of the battery. It is also possible to integrate FPGA applications for faster interaction with the BMS under test. This opens up new ways to emulate cutting-edge technology, such as online electrochemical impedance spectroscopy, with high precision.

The new cell voltage emulation board ensures cell voltage generation with high precision, down to 300 µV. With the support of peak currents of up to 20 A per channel and high-precision current measurement, even the most sophisticated cell balancing scenarios can be emulated. Integrated fault simulation lets users simulate electrical faults such as short circuits or cable breaks as well as defective battery cells. dSPACE will successively complement the modular system design for testing BMS systems with additional emulation boards, for example, for emulating temperatures and high voltages.

The modular concept makes the system scalable and flexible. Moreover, a new safety compartment concept makes it easy to wire the cell channels, reduces the length of the wires to the test system, and allows for easy calibration of the individual cells.

“With the new cell voltage emulation board and the scalable system concept, we present a powerful solution for testing BMS systems at the high-voltage level that satisfies even the most demanding test requirements. Our customers will be able to effectively validate and optimize their BMS, thereby benefiting from shorter time to market,” says Stefan Walter, Product Manager for Electromobility and Electric Drives at dSPACE.

www.dspace.com